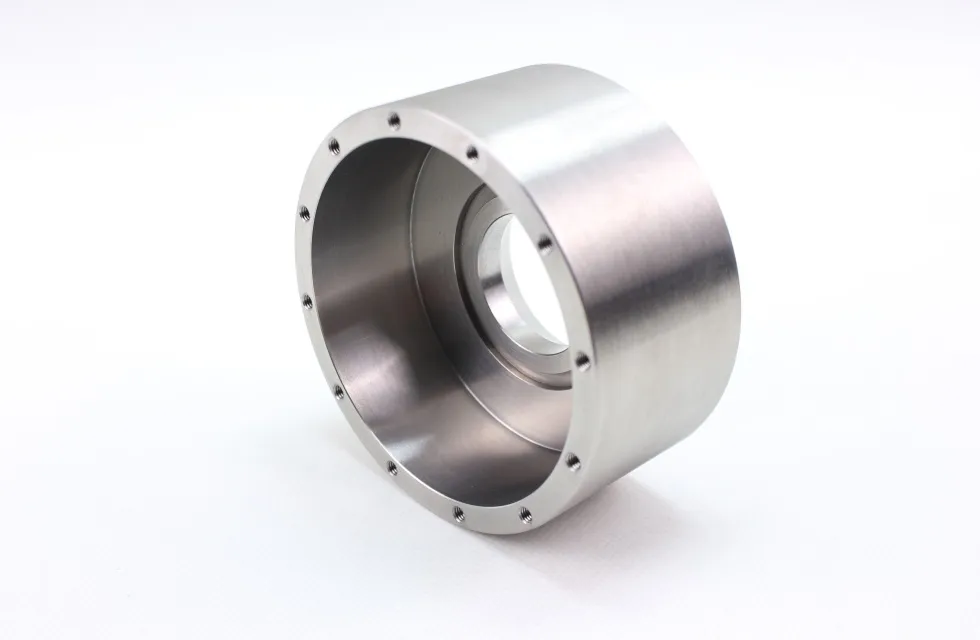

97% Tungsten heavy alloy for printing equipment-– High-Density Precision Components

| Payment Type: | T/T |

| Incoterm: | FOB,CIF,EXW,FCA,Express Delivery |

| Min. Order: |

2 Piece/Pieces |

| Transportation: | Ocean,Air,Express |

Attributes

Model No.: JDTG-CM-050

Brand: ZZJD

Place Of Origin: China

Material: Tungsten

Density: 18.50±0.15g/cm³

Color: Natural

Size: Support customization

PACKAGING & DELIVERY

Selling Units :Piece/Pieces

Package Type : Standard export packing

DESCRIPTION

Tungsten Heavy Alloy for Printing Equipment – High-Density Precision Components

Why Tungsten in Printing Equipment?

Tungsten heavy alloys (WNiFe, WNiCu) are ideal for high-speed, high-precision printing machinery due to their:

Exceptional Density (17-19 g/cm³) – Provides vibration damping for sharper prints.

Wear Resistance – Outlasts steel in abrasive environments (e.g., inkjet nozzles).

Thermal Stability – Low thermal expansion maintains tolerances under heat.

Corrosion Resistance – Withstands solvents, inks, and cleaning agents.

Key Applications in Printing

Component Alloy Type Benefits

Print Cylinder Balancers WNiFe (95% W) Eliminates wobble in rotary presses

Inkjet Nozzle Plates WCu (90% W) Resists clogging, extends service life

Vibration Dampers WNiFe (97% W) Reduces blur in high-speed digital printers

Doctor Blades WNiCr 3X longer lifespan vs. steel blades

Gravure Rolls WCo Maintains sharp grooves for precise ink transfer

Technical Advantages Over Steel/Aluminum

50% heavier than steel – Improves momentum control in moving parts.

Hardness (280-320 HV) – Resists scratching from pigments/abrasives.

Non-magnetic – Critical for MRI-safe printing facilities.

#PrintingTechnology #TungstenComponents #PrecisionPrinting #IndustrialAlloys

Performance Comparison

Property Tungsten Alloy Stainless Steel Aluminum

Density (g/cm³) 17-19 7.9 2.7

Wear Rate 0.02 mm³/Nm 0.15 mm³/Nm 0.3 mm³/Nm

Thermal Expansion 4.5 µm/m°C 17 µm/m°C 23 µm/m°C

Customization Options

Precision Machining: ±0.005mm tolerance for rollers/blades.

Coatings: PTFE, DLC, or ceramic for enhanced ink release.

Form Factors: Rods, plates, or CNC-finished parts.

Industry Use Cases

Packaging Printing: Tungsten doctor blades for consistent ink application.

3D Printing: Dense build plates to reduce vibration artifacts.

Banknote Presses: Tamper-proof tungsten components for security.

EN

EN AR

AR FR

FR DE

DE HI

HI IT

IT JA

JA KO

KO PT

PT RU

RU ES

ES ID

ID LV

LV VI

VI HU

HU MS

MS GA

GA BE

BE YI

YI EU

EU