Tungsten screws – Precision Balancing for High-Performance Systems

| Payment Type: | T/T |

| Incoterm: | FOB,CIF,EXW,FCA,Express Delivery |

| Min. Order: |

100 Piece/Pieces |

| Transportation: | Ocean,Air,Express |

Attributes

Model No.: JDTG-TS-024

Brand: ZZJD

Place Of Origin: China

Material: Tungsten

Density: 18.10±0.15g/cm³

Color: Natural

Size: Support customization

PACKAGING & DELIVERY

Selling Units :Piece/Pieces

Package Type : Standard export packing

DESCRIPTION

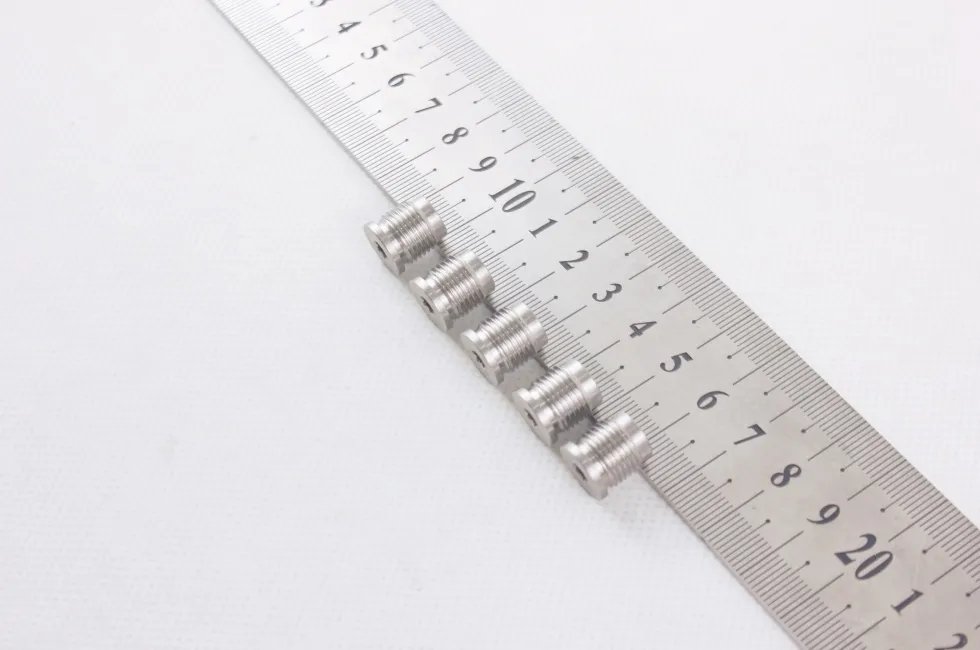

Tungsten Alloy Counterweight Screws – Precision Balancing for High-Performance Systems

Why Tungsten?

Tungsten heavy alloy (WNiFe, WNiCu) screws provide superior weight distribution due to:

✅ Ultra-High Density (17–18.5 g/cm³) – 2.5X heavier than steel in the same size.

✅ Compact Design – Achieve precise balance without bulky components.

✅ Corrosion Resistance – Withstands harsh environments (saltwater, chemicals).

✅ Vibration Damping – Reduces harmonic resonance in rotating systems.

Product Range

Type Material Key Features Applications

Adjustable Counterweight Screws WNiFe (95% W) Fine-tuning for dynamic balance Robotics, aerospace actuators

Set Screws WCu (90% W) High thermal conductivity Laser systems, CNC machinery

Micro Counterweights WNiCr (1–5mm Ø) Precision small-part balancing Watchmaking, medical devices

Technical Specifications

Thread Sizes: M2–M20 (metric), #4-40–1/2" UNC (imperial)

Tolerances: ±0.01mm (grinding/polishing available)

Surface Treatments: Black oxide, Ni plating, passivation

Load Capacity: Up to 1,000 N tensile strength

Industry Applications

Aerospace: Rotor blade balancing in helicopters/drones

Automotive: Crankshaft/flywheel balancing in performance engines

Semiconductors: Wafer stage counterweights in lithography machines

Medical: MRI component balancing (non-ferromagnetic)

Performance Comparison

Property Tungsten Screw Stainless Steel Brass

Density (g/cm³) 17–18.5 7.9 8.4

Corrosion Resistance ★★★★★ ★★★☆☆ ★★☆☆☆

Cost Efficiency $$$ (but longer lifespan) $ $$

Custom Options

Head Types: Hex, socket, slotted, or custom drive designs

Hollow Designs: Weight reduction with internal channels

Engraving: Laser-marked weight/part numbers for traceability

#PrecisionBalancing #TungstenScrews #AerospaceEngineering #VibrationControl

EN

EN AR

AR FR

FR DE

DE HI

HI IT

IT JA

JA KO

KO PT

PT RU

RU ES

ES ID

ID LV

LV VI

VI HU

HU MS

MS GA

GA BE

BE YI

YI EU

EU